Nailless structure, easy to disassemble and assemble

On-site packaging experience like never before ¨C simple, convenient and fast

X-Bason packaging adopts the method of connecting galvanized steel strip with plywood, using high strength The environmentally friendly anti-rust galvanized steel belt connects the box board, and the packing and secondary unpacking are simple, fast,No special tools are required, and it is as convenient and helpful as using a "Lock lunch box".Enterprises have greatly improved packaging efficiency.

Rugged and safe, rock solid

It only takes a few minutes to disassemble and assemble a single box, and the packaging efficiency is much higher than that of traditional wooden boxes.

Nail-free structure, safe and convenient, say goodbye to hand saws, nails and other tools.

No need for a professional packer, anyone can operate it.

Xin Baisheng galvanized steel strip wood packaging box is made of high-strength environmentally friendly plywood, the box body is connected by high-strength toothed galvanized steel belt, the principle is that the overall force of the box, whether it is assembly or transportation, there will be no loosening, and at the same time avoid missing nails, open nails, less nails, rough process, dust, rain, improper structural treatment, and scattered shelves caused by box collision during transportation; It ensures the safety of the product, ensures the integrity of the customer's receipt, and ensures zero accidents for on-site packaging personnel due to the non-nailing operation. At the same time, we have passed a series of strict tests such as pressure test, impact test, vibration test, drop test, moisture-proof test and so on conducted by Shenzhen Institute of Metrology and Quality Inspection, to meet international product transportation and packaging safety standards. Under the same material conditions, the performance of Xin Baisheng galvanized steel belt wooden box exceeds that of traditional wooden boxes.

Material: High quality plywood, hot-rolled galvanized steel strip

Specification: Can be customized according to customer needs

Type: Two sided or four sided fork, crane lifting

Fumigation and Disinfection Certificate: No fumigation required

Plant quarantine certificate:

Quarantine free dynamic load: 10-4000kg

Static load: 10-6000kg

characteristic:

1. Connected by high-strength galvanized steel strips, it has excellent load-bearing and compressive performance, making it more sturdy and durable

2. More lightweight and aesthetically pleasing, capable of spray printing, enhancing customer product image

3. The weight is only 30% to 40% of traditional products, and it has good stacking performance

4. Excellent climate tolerance, adaptable to various harsh climates from tropical to cold regions

5. Suitable for long-term transportation and storage, can be reused multiple times

6. It can be disassembled and assembled freely, effectively saving storage space and reducing transportation costs

7. Meets the transportation packaging requirements for heavy, large, transportation sensitive, and high-value products

8. Compliant with the quarantine inspection requirements for export packaging, it is an exempted product for export inspection

9. Can process any specifications and sizes according to customer needs

10. It can quickly and conveniently package items, especially large boxes, in real-time on site

Subverting tradition!

Beautiful appearance, sturdy and durable, environmentally friendly and low-carbon

Simple, easy-to-use, mature and reliable packaging usage plan

A single packaging box can be reused up to 10 times

Compared with traditional wooden boxes, it can help enterprises reduce the total packaging cost by 30%

Compared with traditional wooden boxes, it saves more than 50% of plywood materials. Customers calculate by purchasing 100 boxes of 1 cubic meter size per month,

Reduce a few hectares of deforestation annually

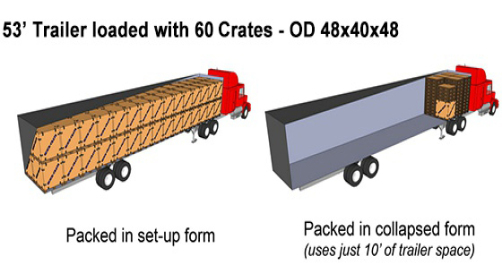

Foldable and stackable

Optimize warehousing and transportation

Advanced production technology

The most outstanding wooden packaging box with millimeter level precision and consistent quality

We not only focus on product quality, but also take into account the image of the enterprise. X-Bason steel belt wooden box adopts a buckle packaging method, which is simple, beautiful, and generous. The packaging image has been greatly improved, and the product and company image have been greatly enhanced. The roughness of traditional packaging boxes greatly reduces the added value of products made in China, and also fails to reflect the potential value of the products. However, Xinbai steel strip wooden boxes have clearly solved this problem. The plug-in packaging box is an internationally recognized high-end packaging product with obvious advantages, and is the preferred product to reflect the company's brand image and distance itself from peers.

The folding volume ratio is 5:1

Xin Baisheng galvanized steel strip wooden box board can be folded and transported, without any tools can be easily assembled, the volume after folding is less than 15% of the original, the thickness is about 180-230mm, the minimum volume is almost equal to the size of a bottom pallet. The compact size reduces space and allows more Xin Baisheng steel belt wooden boxes to be passed within a transport unit, thus reducing logistics costs and warehousing costs.

Up to 10 layers can be stacked

When in use, it can be stacked according to customer needs, with a maximum of 10 layers stacked without the need for shelves, increasing space utilization.

Own factory, mechanical automation production

100% self owned factory, all packaging boxes are produced by our own factory, ensuring comprehensive product quality, response time, and delivery speed. At the same time, continuously improve the level of production automation and achieve over 90% of production automation.

Advantageous quality control, millimeter level production schedule

Strictly implement various operating procedures and conduct regular assessments. Vigorously promote "6S management". Strict supplier screening, rigorous inspection and acceptance of incoming raw materials. Strict finished product inspection to prevent unqualified products from entering the market. At the same time, with advanced wooden packaging box production equipment and technological level, all the wooden packaging box products we produce have achieved millimeter level accuracy.

Excellent packaging design ability

A professional team of packaging designers with years of experience in the packaging design industry. Using cutting-edge 3D and graphic design software such as Solid edge, AutoCAD, etc., to meet the needs of different customers.

Direct export without fumigation

Improve export efficiency and reduce export costs

Comply with the ISPM15 standard and ISPM (International Phytosanitary Measures) requirements for heat treated solid wood packaging for export to reduce pest infestations. But only regulate solid wood products. Our wooden boxes are mainly made of OSB (oriented strand board) or plywood, and the raw materials are made by high-temperature heating, which meets the export standards of ISPM15 specifications. Therefore, there is no need for fumigation or heat treatment when exporting, and the time is short. Customs clearance is convenient, timely, and simple. ISPM

Ïà¹Ø¹æ¶¨ÔÎÄISPM-15 Regulations: page 7, section 2.1

" The following articles are of sufficiently low risk to be exempted from the provisions of this [ISPM-15] standard: -wood packaging made wholly of processed wood material, such as plywood, particle board, oriented strand board [OSB] or veneer that has been created using glue, heat or pressure, or a combination thereof."

Relevant regulations of Chinese Customs

The appearance is no longer the same as before

High end and beautiful, with a high-end appearance